| In my third year internship I learned a massive amount of skills and enjoyed the working environment.

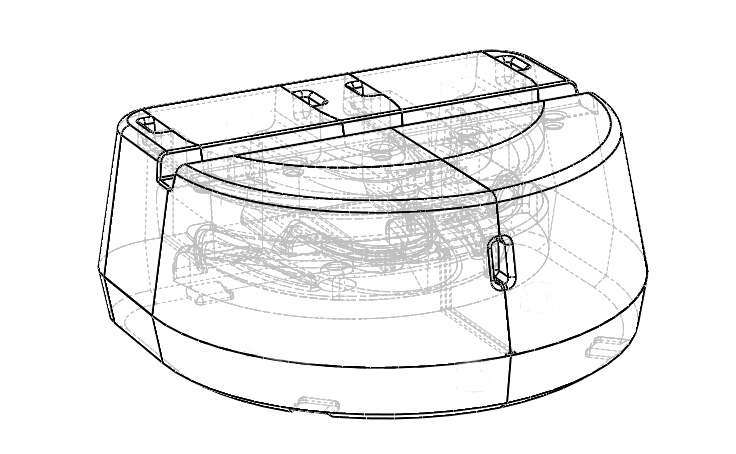

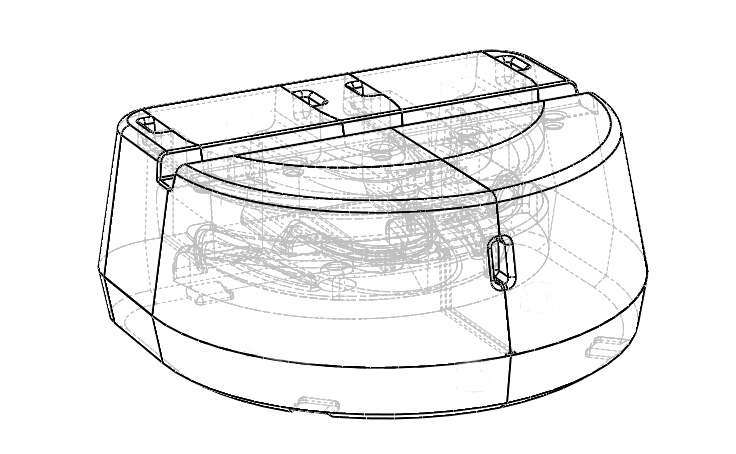

A great and unique skill I learned, was to create a Solidworks mold model. I learned to create a complete and working mold. The Solidworks model could be used to 3D print a mold. After the mold was printed, it could be injected with a polymer. This way an actual prototype was created.

I learned a lot about the injectionmolding process. I used all these skills to inject a lot of molds. Normally the molds were made out of steel or 3D printed polymers.

When a product came out defect, it was my task to find the error and redesign the mold.

When a product was finished, it needed to be tested. After testing, the results were reported by company standards. The goal was to improve the complete product by testing.

Sometimes the material was not suited for production. In this case the material was improved by material research and were discussed with diffrent suppliers. This methode was a very effective way to improve the process. |

-

Internship Dental Robotics

Internship experience at Dental Robotics

-

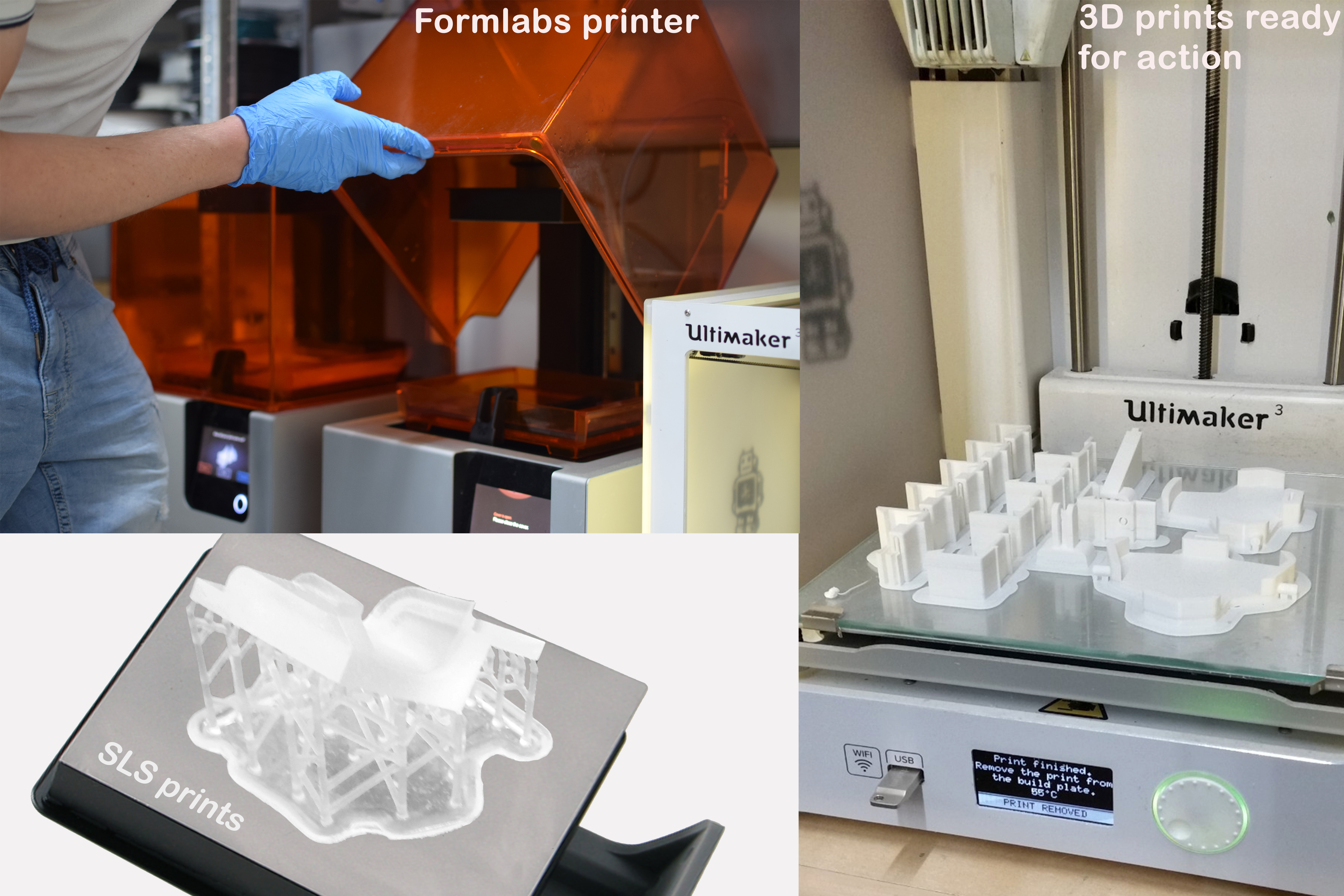

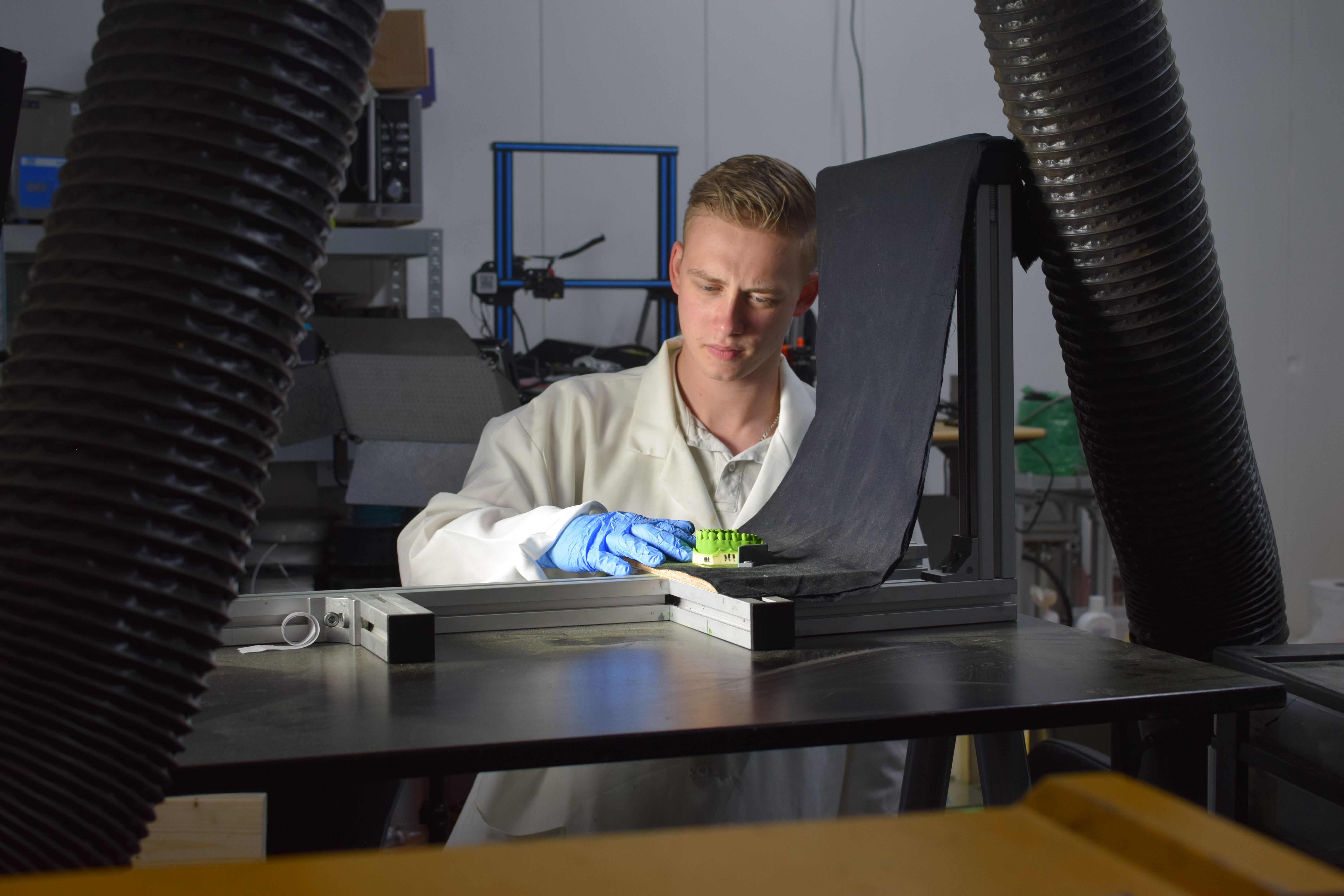

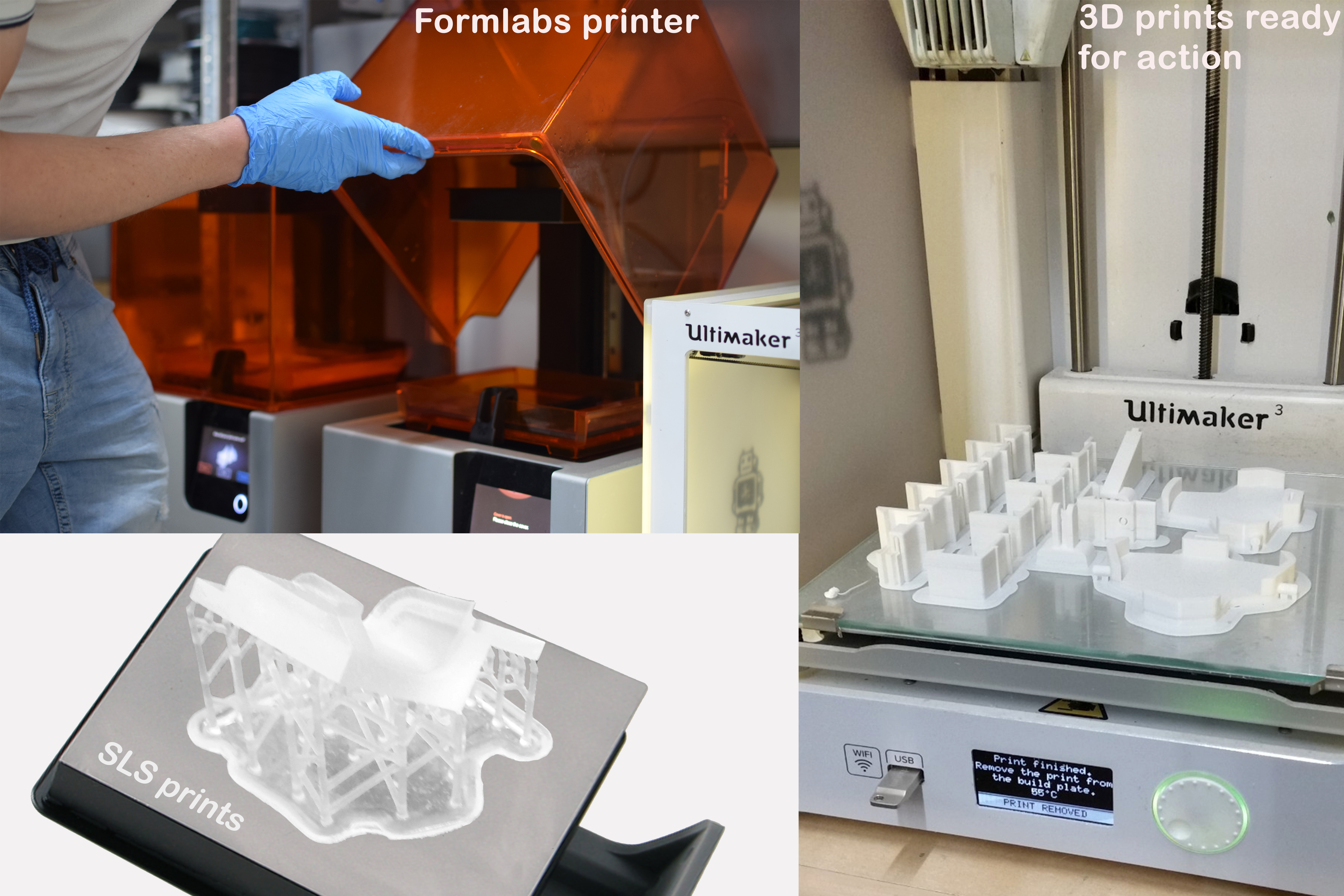

After modeling the mold or prototype, I 3d- or SLS print the test product to make it real. You can see how the mold or prototype will act and very importand what need to be optimised for real production.

-

Using SLS and 3d printing to print molds and first prototypes and iteratie fast.

-

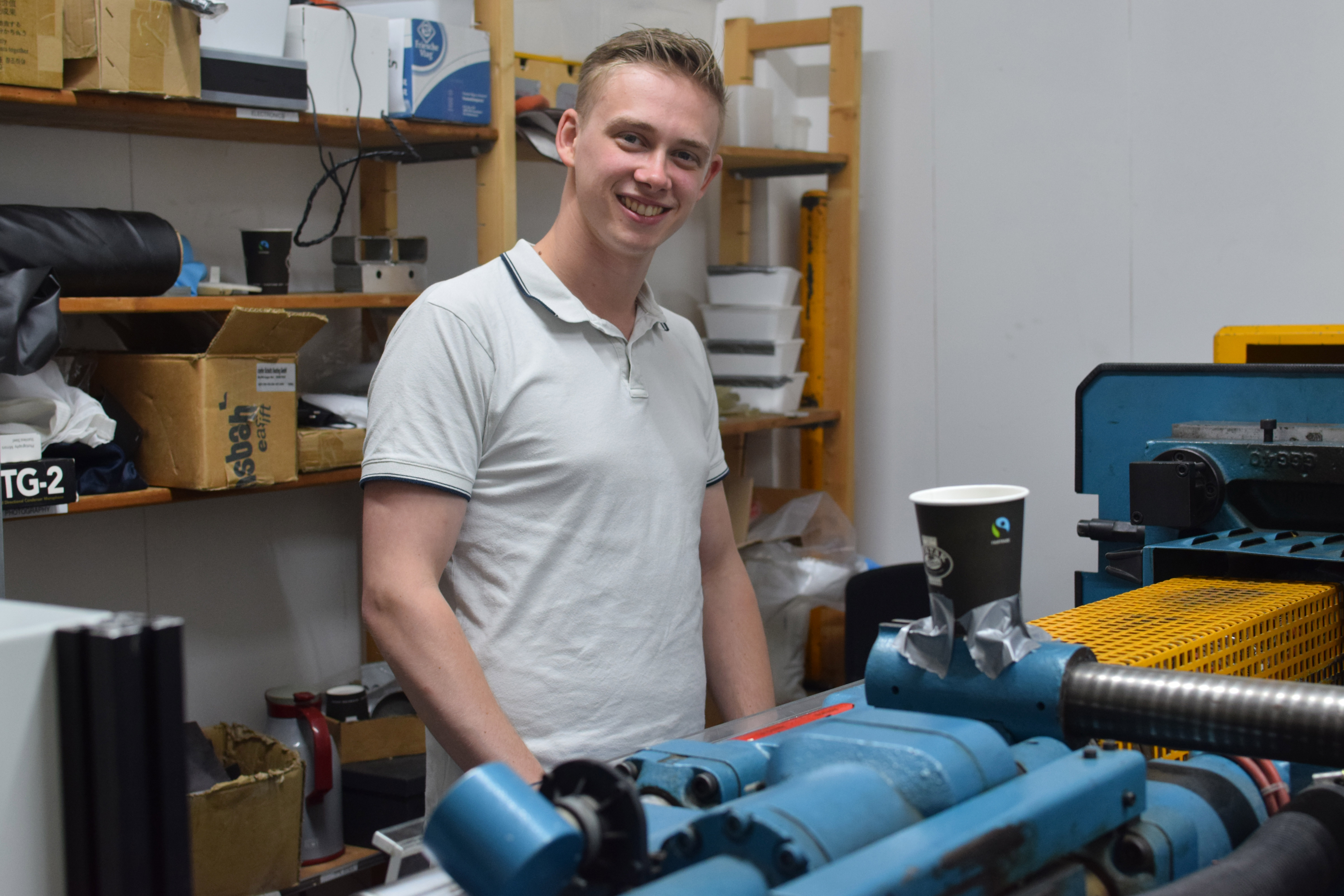

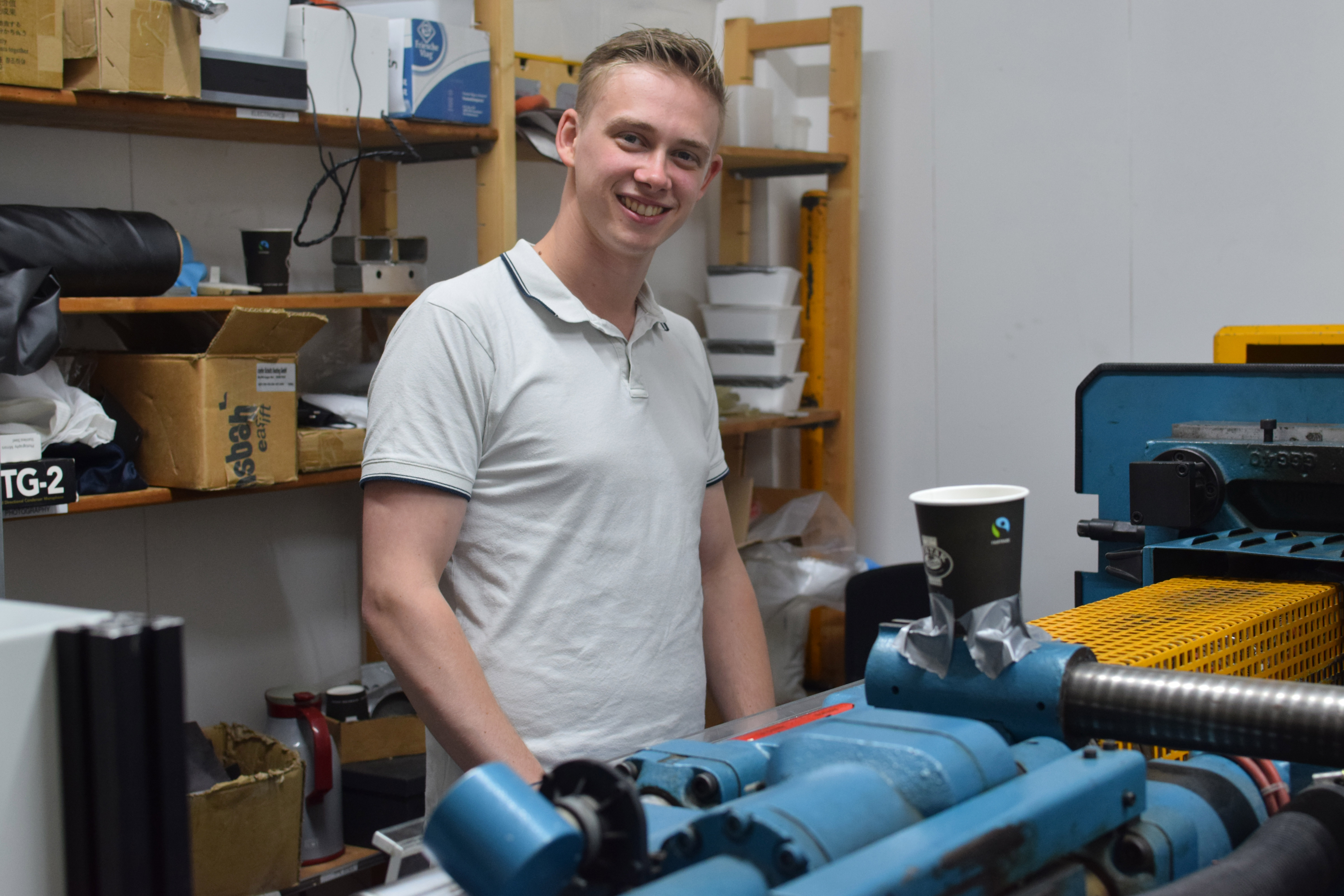

Now the printed molts can be injectionmolded. I have learned a lot about this process. How to use these machines and changing the importand parameters. While- or after injectionmolding recognizing the error in the prototype or the molt is one of the many skills I learned.

-

Self worked on Molddesign

A product with mould and fully developed production version I have worked on. Each version was highly optimised to injectionmold this part very clean and fullfilling the requirements. Learning to make molds in Solidworks wasn't easy, but when you just do it and learn from your co-workers when you struggle, you can learn a lot. After this few more diffrent molds were moddeled and tested for injection molding.

-

Production injection molding machine

Working with some bigger injection molding machines and learned how they work in global line to help in the production . Some difficulties, where to see how to optimise a product, when it comes out for instance unfilled and how to tackle this by changing machine settings or translating this in an other mold design.

-

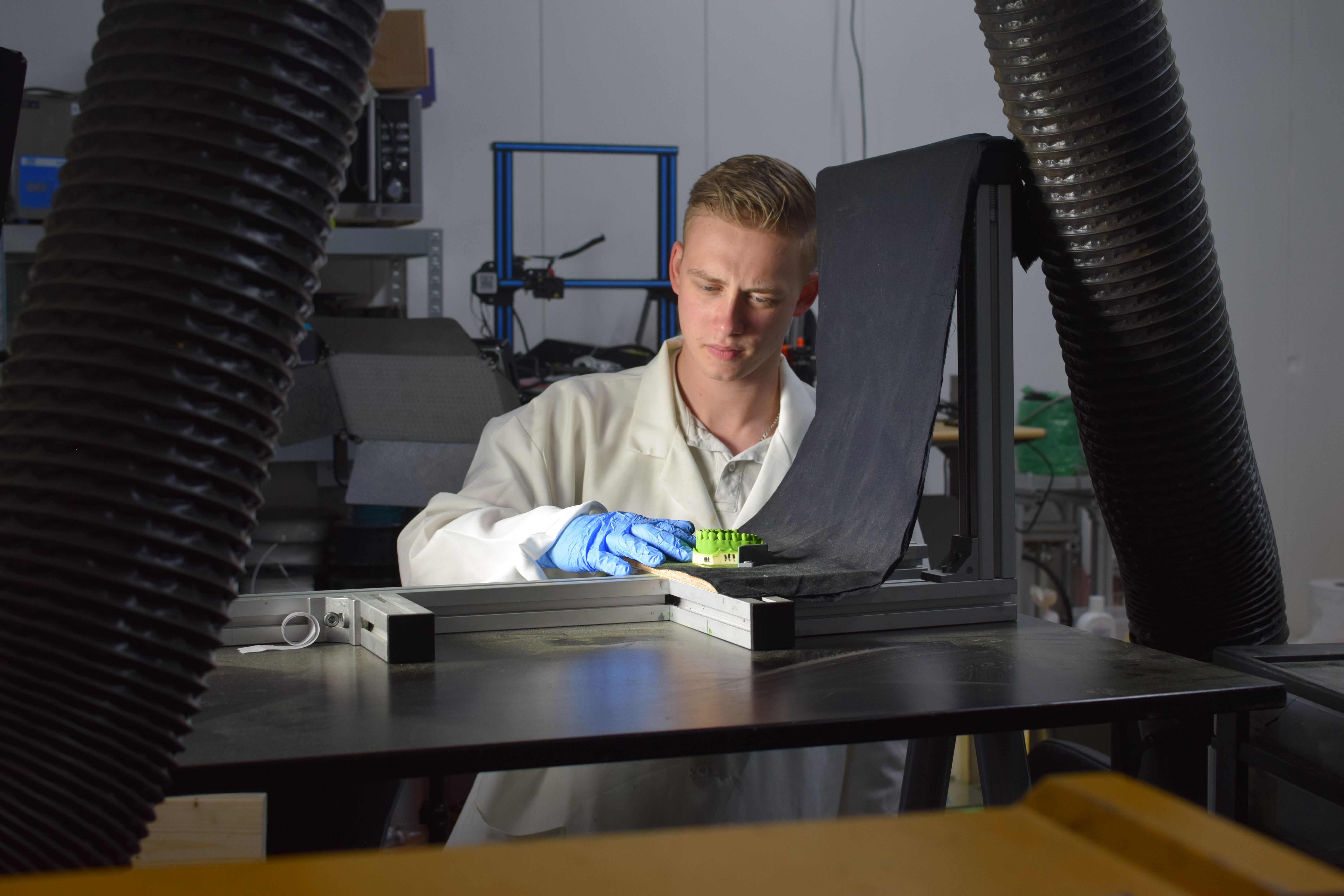

When a prototype/product is made, lots of performance test needed to be done. All to asses the increased value of the product. Learned how to make propper photos and how to document the test results by the company standards. All to innovate the product to optimise the performance and to see how product you have worked preforms.

|