| The minor Product Design for Healthcare helped me with designing a complying and human helping product by focusing more on user centered design. Our client: Martin van der Weg, Stichting Bestaanskracht. Project Cliënt Vinder (smartwatch) for patients with schitsofrenia. We learned how to implement features and ergonomics by interviewing caregivers and our experienced client.

The assignment is build-up of two elements. At first finishing the design phase after this the testing phase of a prototype. This part needed to be ready for production.

The other element of the assignment is to design different parts that form a new integral solution when combined.

The skills I improved during this Minor:

-Improvement on User-centered design by designing with necessary helping features based on interviews and analysis.

-Solidworks 3d modeling and optimizing these models

-Rapid-Prototyping (well-fitting models)

-How to set up a better communication and keep communicating with for instance: a client, mechanical-professionals, suppliers and care givers. |

-

Minor Product Design for Health Care 2

A minor specialiced to design a product for the healthcare. Client: Stichting Bestaanskracht

-

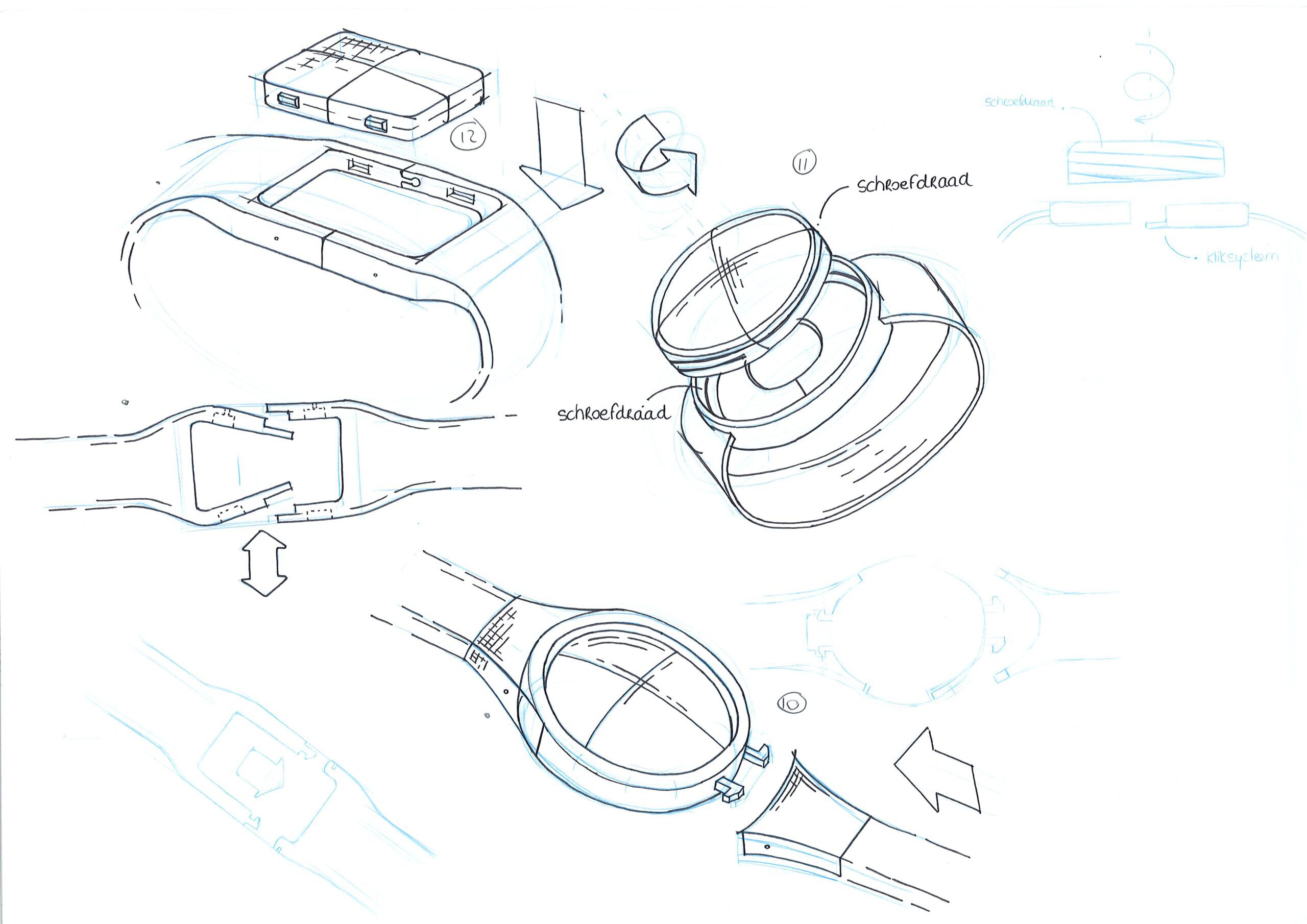

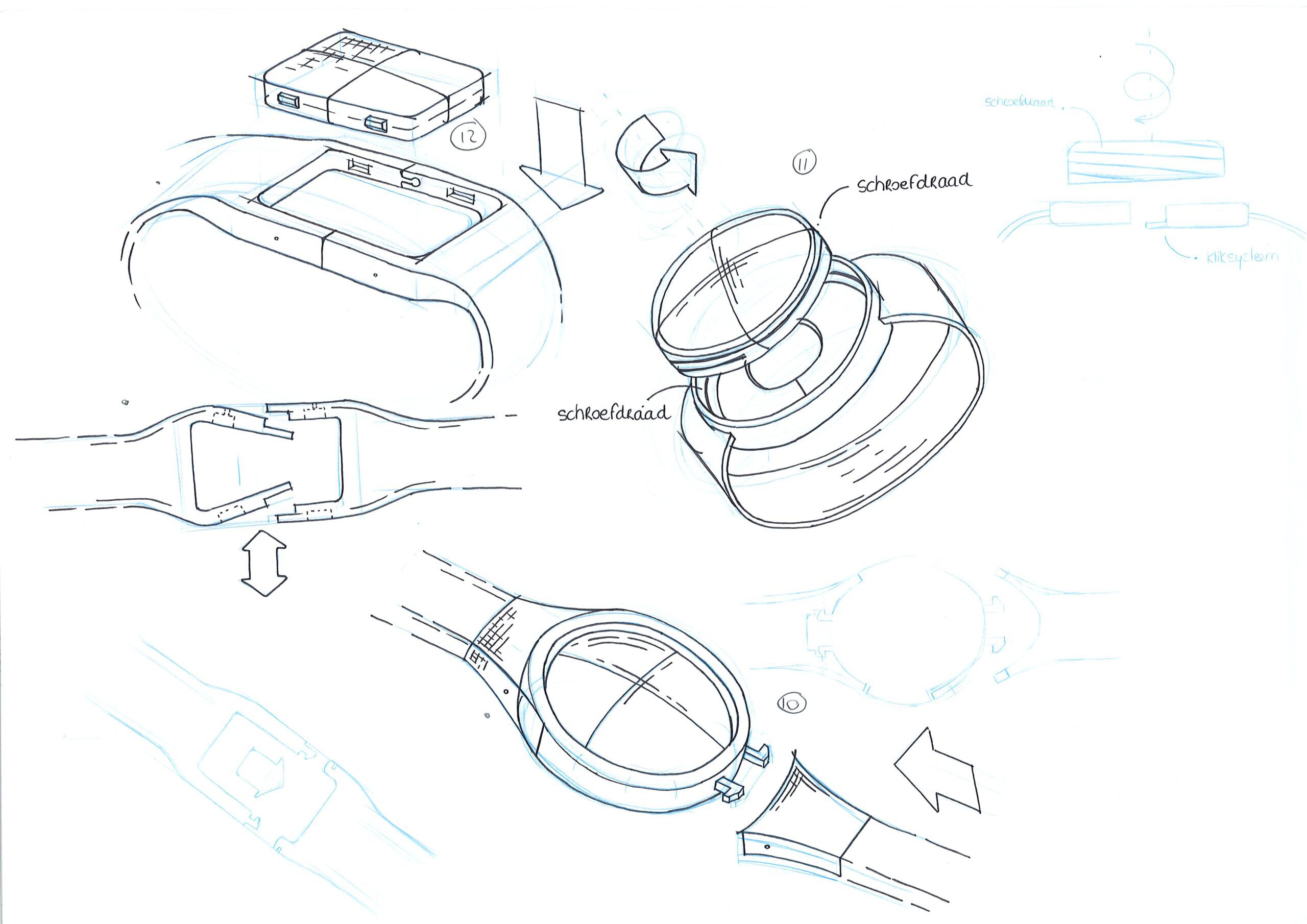

Examples of problem solving sketches of the locking mechanism are shown. The competition research and learning to contact experts made it possible to expend the selection of ideas and integrate these ideas into concepts.

-

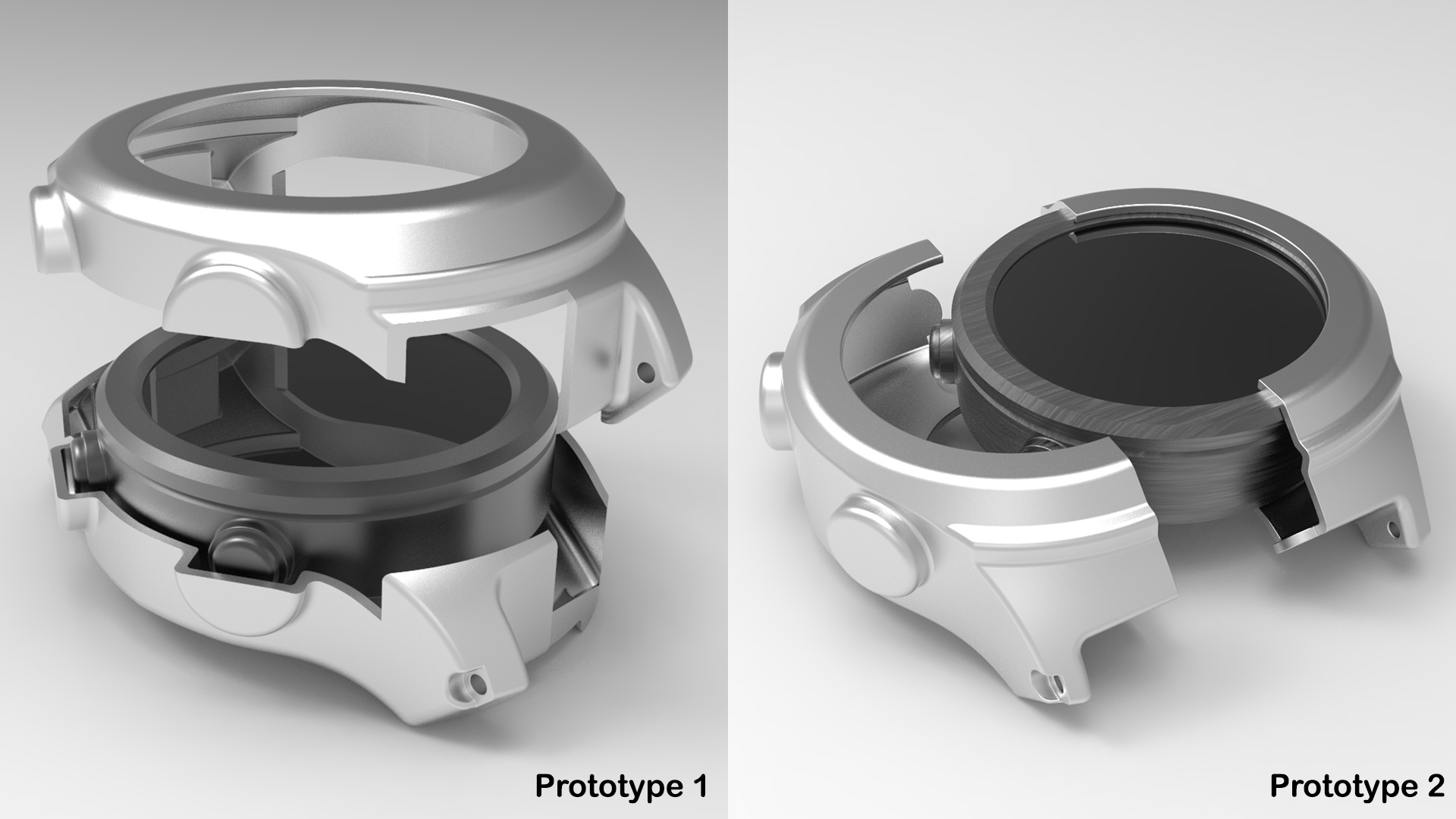

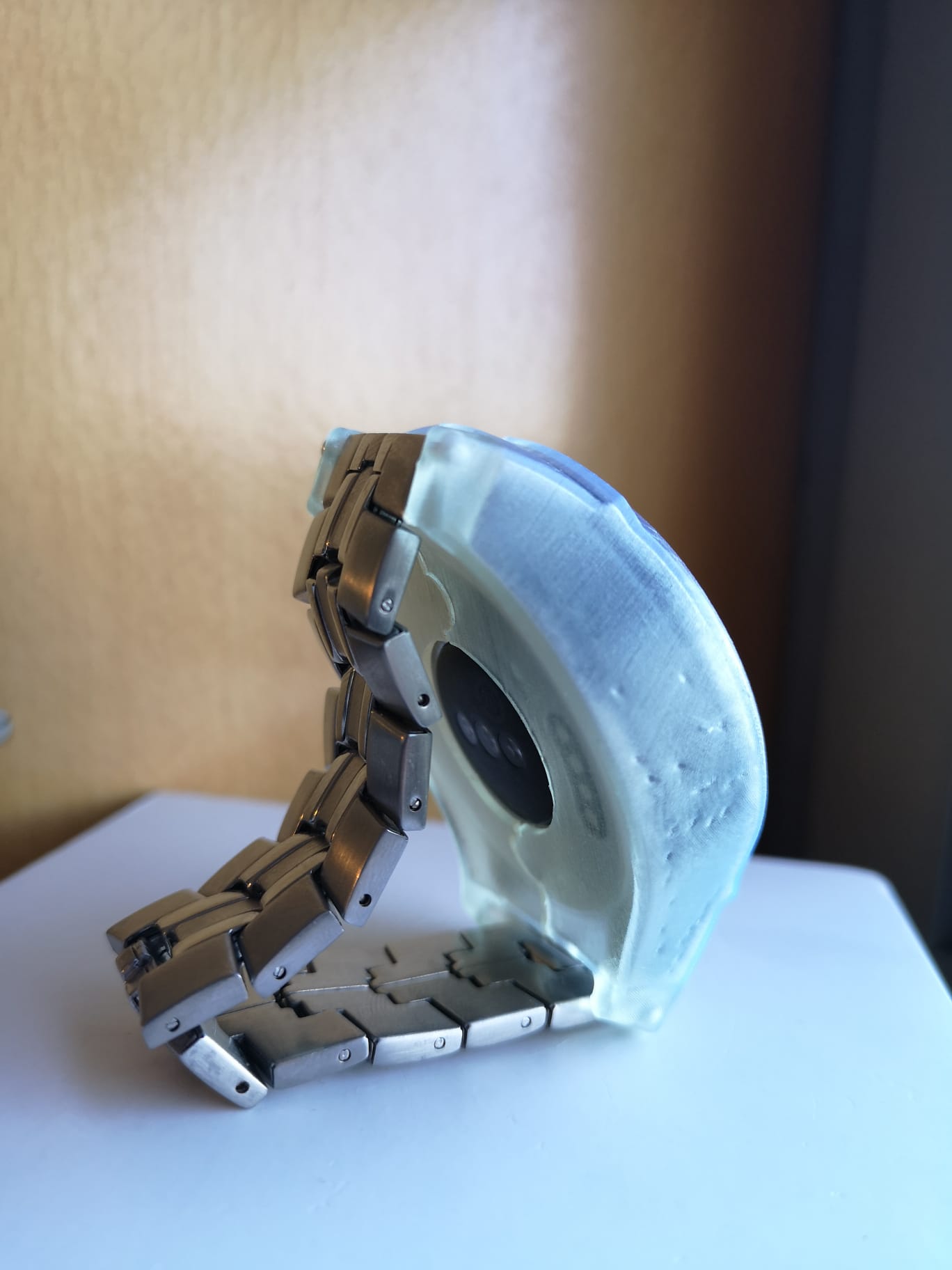

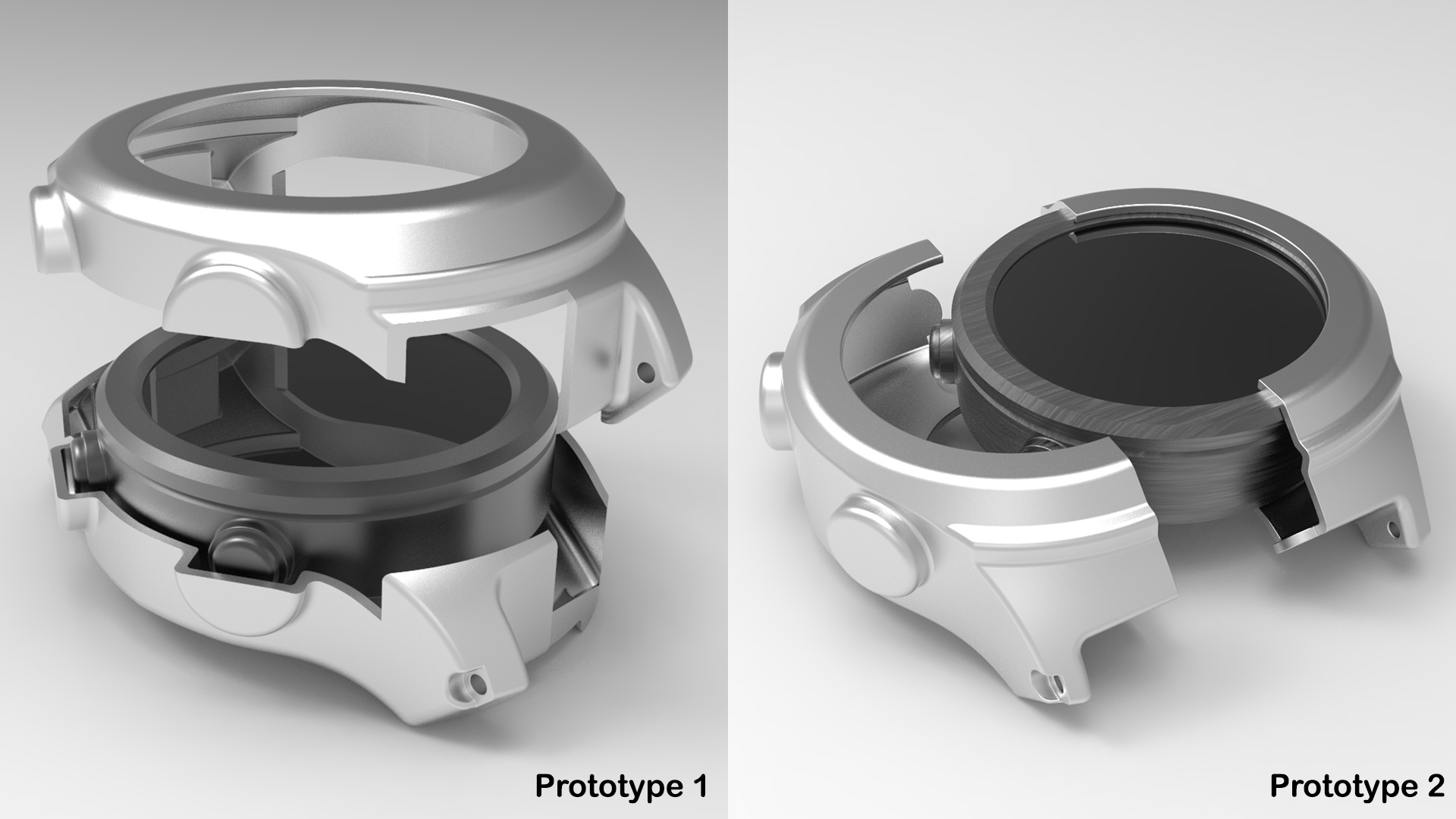

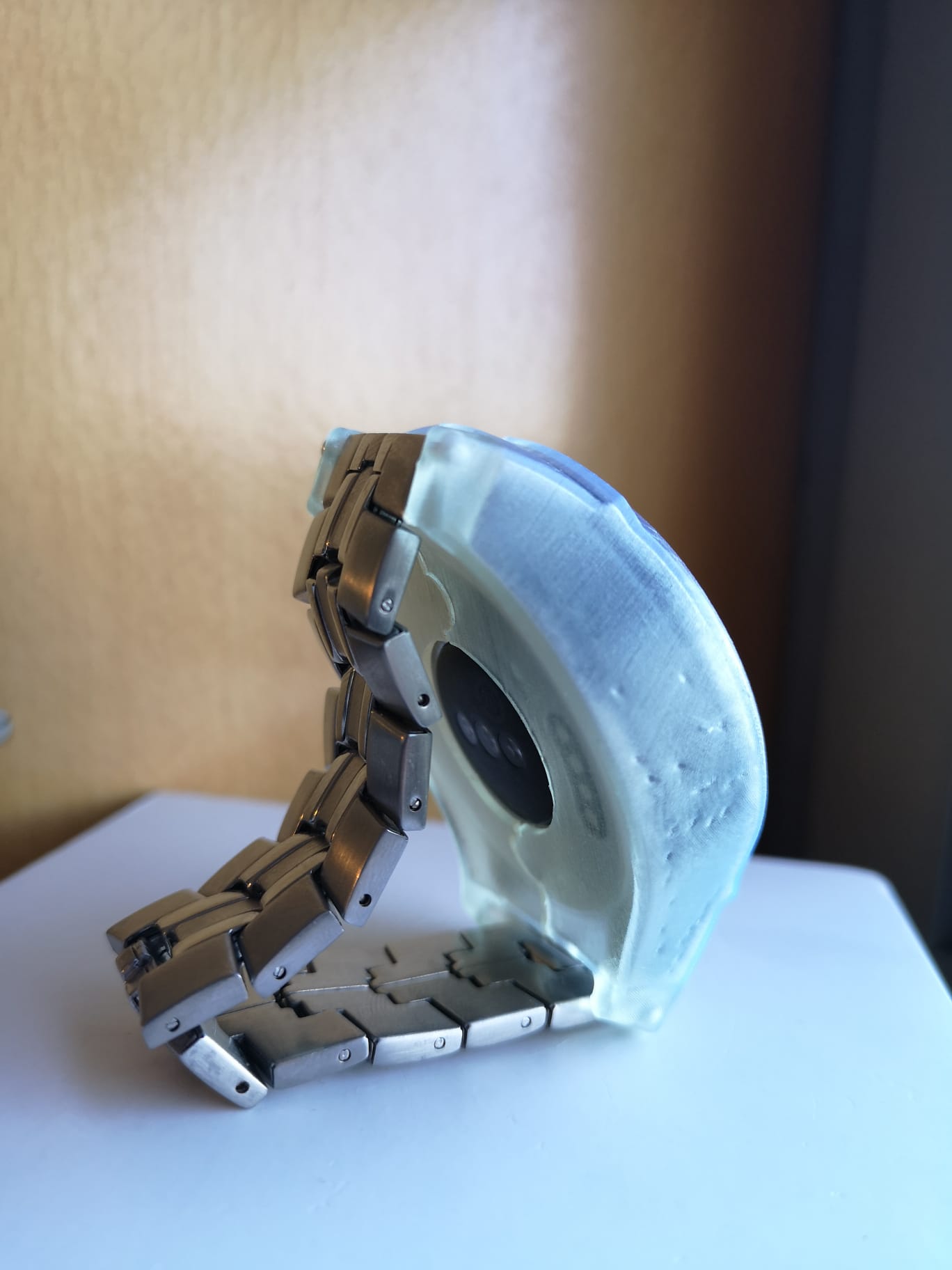

One part of my job was to support the prototype optimisation. How? SOLIDWORKS models for form optimisation and ergonomics improvements, using Rapid-Prototyping to test the fit on the Huawei watch. Contacting prototyping suppliers for the best price and discussing the technical characteristics.

-

Modelling in Solidworks and discussing the best option to optimise the build-up anad split line with use of Rapid-Prototyping. With these prototypes we learned to test the function and user-friendliness of casing. Rendering the products was a skill optimistion in this minor.

-

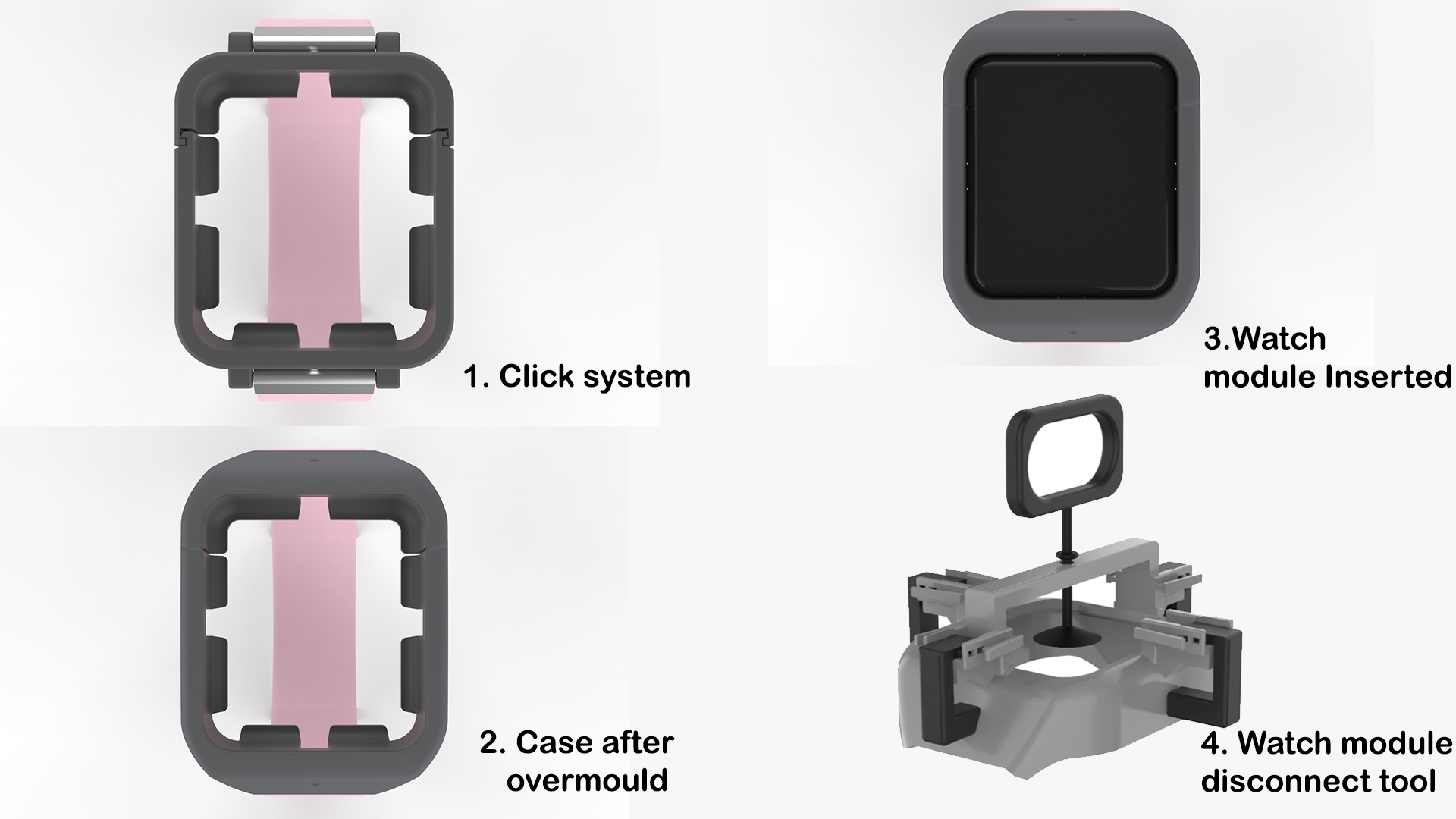

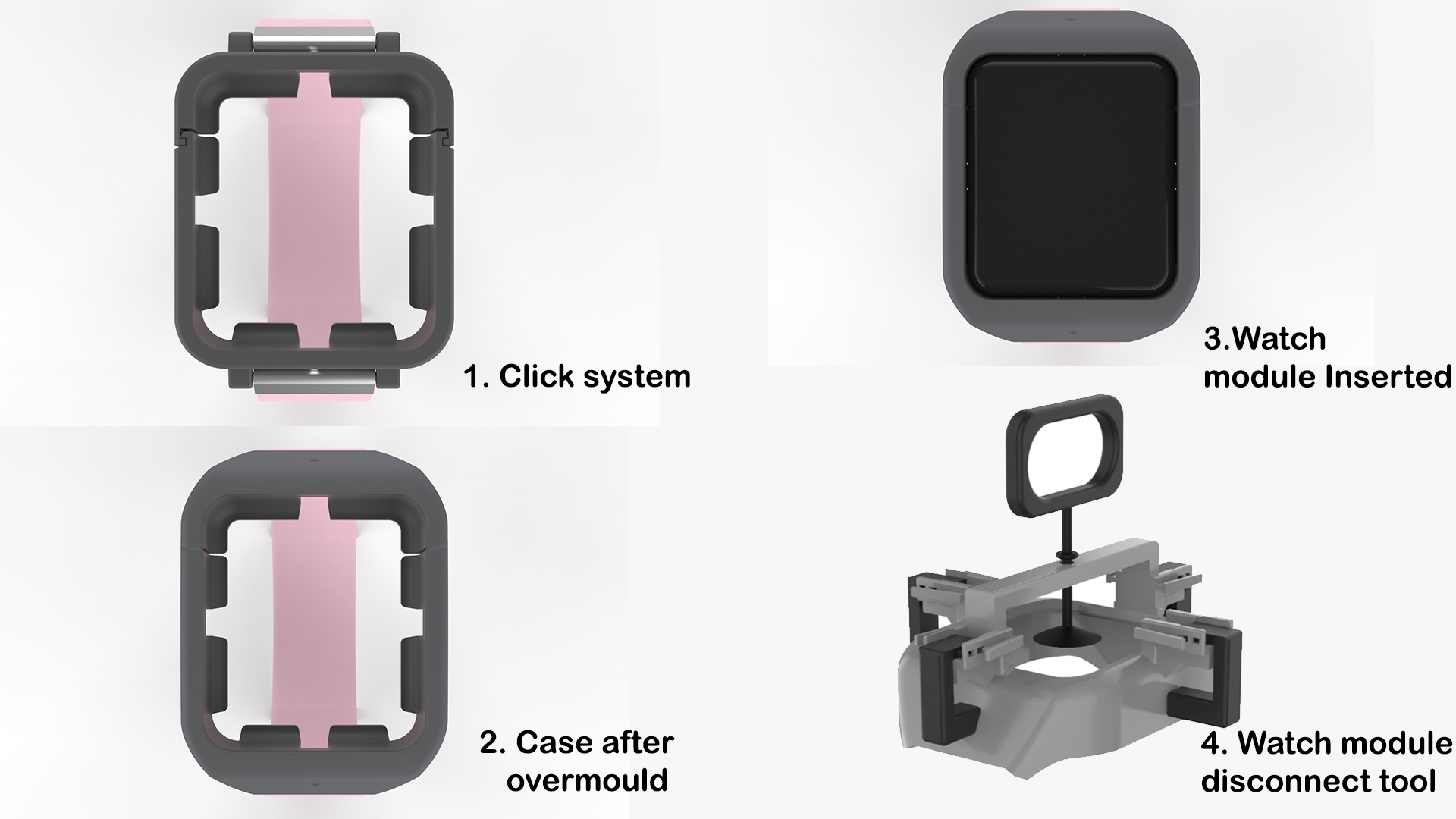

After all the testing to comfort/user-friendliness, the challenge was to design a strong and safe opening system to protect the user and can be opened by caretakers with a fast and safe opening tool. I set up meetings with professionals and teachers and optimise the fine mechanics.

-

A end result of the final watch case with working mechanism.

-

A end result of the final watch case with working mechanism.

-

Build-up New Cliënt Vinder Watch

It was the challenge to design a self-locking hinge into the module, the inspiration was found in similar products. The product will be injection moulded and need to be designed for manufacturing. Another challenge was to combine form with producibility by slightly adjusting the model, optimising undercuts, draft angles and mould opening directions to make the product ready to injection mould.

-

Final renders new Cliënt Vinder design

The module could be chosen in a round and square version, both ready for mould design, after the mould design production.

|